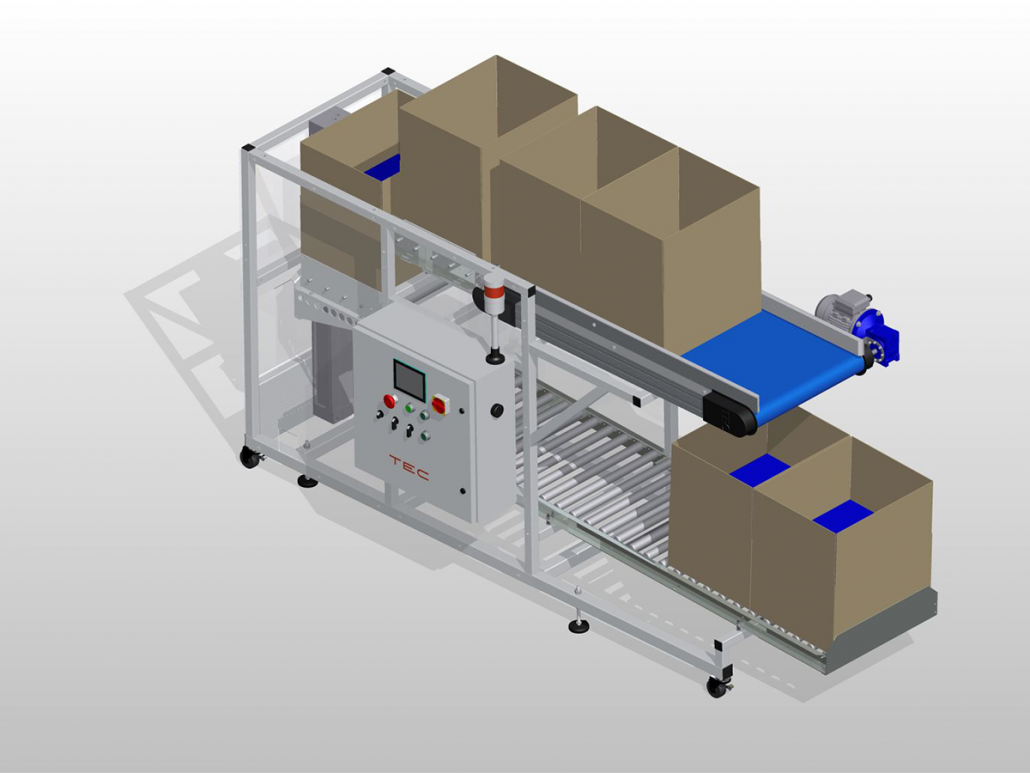

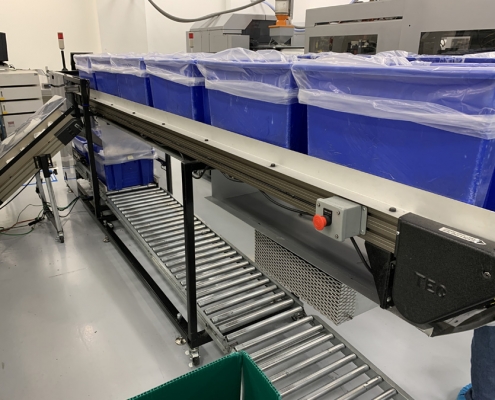

Over/Under Box Filling System

Over/Under Box Filling System

By Weight or By Cycle Count

An operator places the empty boxes on the TEC belt conveyor (upper level). The conveyor starts, shifting the first box in the queue onto the elevator platform. The elevator descends to the lower level where a pneumatic arm engages and retracts, shifting the empty box to the filling position. A photo-eye signals the parts-feed device (can be a conveyor or a chute) to commence filling. During the filling sequence the elevator platform will retrieve the next empty box in the queue. Once the box is filled, the parts-feed device stops. The pneumatic arm engages and retracts, shifting the empty box onto the filling platform, displacing the filled box onto a gravity roller conveyor. The box filling sequence continues until there are no more boxes left in the empty box queue. At this time, an audible alarm will engage.

Customer Requirements

- Supply the box/tote size.

- Specify the number of boxes/totes to be filled.

- Specify if filled by cycle count or weight.

- Define how box is to be filled (parts feed conveyor, robot, or chute).

Please consult factory for additional information.

Fore more information about TEC Engineering’s products or services, please contact us online or call 508-987-0231.

TEC Engineering Corp

- 31 Town Forest Road

- Oxford, MA 01540

- 508-987-0231

- 508-987-0093

- sales@tecautomation.com

- TEC Sales Representatives

About TEC

Conveying and Automation Equipment for the Plastics and other Industries.

Products

Learn about the conveying and automation equipment TEC offers.

Copyright © 2025 – TEC Engineering

Website by Cold Spring